The Art and Science of Jewelry Plating

Enhancing Durability, Allergy-Free Wear, and Aesthetic

Jewelry plating involves applying a thin layer of metal—such as silver, gold, rhodium, or platinum—onto a base metal to enhance its appearance and durability. This process not only adds a luxurious finish to jewelry but also provides a protective layer against wear and tear.

The Benefits of Jewelry Plating

Enhanced Durability:

Plating creates a resilient shield, safeguarding jewelry against scratches, tarnishing, and other forms of wear, ensuring its longevity.

Comfortable Allergy-Free Wear:

By covering base metals that may cause skin sensitivities, plating offers a hypoallergenic solution, ensuring a comfortable and worry-free experience for wearers.

Aesthetic Excellence:

Plating gives designers the chance to create unconventional jewelry by mixing colors and placing accents strategically. This allows for artistic expression and makes each accessory extraordinary and unique.

What Types of Jewelry Plating Are There?

There are various types of jewelry plating techniques available, each offering specific aesthetic and functional benefits. At our state-of-the-art factory in Bangkok, German Kabirski specializes in a select few, employing advanced electroplating methods. This involves immersing jewelry in a solution and using electricity to apply thin layers of metal. It's a meticulous technique that demands skilled professionals to ensure precise coverage and durability. Our expert team excels in this process, creating quirky jewelry pieces renowned for their quality and beauty.

Gold Plating

Gold plating involves applying a layer of gold onto jewelry using an electrochemical process. First, the jewelry is cleaned and prepared. It's then immersed in a solution containing gold salts. An electric current is passed through the solution, causing the gold ions to bond to the metal surface. This process enhances the jewelry's appearance with a luxurious gold finish while providing durability and resistance to corrosion.

White Rhodium Plating

The Bacchus Bunch collection is designed for those who live life unapologetically and embrace their wild side. Each piece in this collection is a testament to boldness and individuality, crafted to be more than just jewelry—it’s an expression of freedom and hedonism. Made from 925 Silver and plated with White or Black Rhodium, 18K Gold, and Anthracite, these designs feature striking natural Amethyst gemstones that capture the intense purple hues and raw beauty of the stone. Whether you're attending a lavish party, an intimate gathering, or simply enjoying a night out, Bacchus Bunch is your perfect companion, reflecting the spirit of Bacchus himself: unrestrained, vibrant, and irresistibly captivating. Embrace the controversy, defy the norms, and let your jewelry make a statement as bold as your lifestyle.

Black Rhodium Plating

Black rhodium plating achieves a bold, dark finish by electroplating jewelry with rhodium that's been alloyed with other metals. This process begins with thorough cleaning and preparation of the base metal. The jewelry is then immersed in a black rhodium solution and subjected to an electric current. The result is a striking black appearance that adds depth and contrast to the jewelry's design, making it a choice for modern and distinctive styles.

Ruthenium Plating

Ruthenium plating involves depositing a layer of ruthenium onto jewelry to achieve a sleek, gunmetal-like finish. Similar to other plating processes, the base metal undergoes cleaning and preparation before being immersed in a ruthenium plating solution. Electrochemical deposition ensures an even and durable coating, providing exceptional hardness and corrosion resistance. Ruthenium-plated jewelry exhibits a unique dark gray appearance that enhances its aesthetic appeal and durability.

Anthracite Plating

Anthracite Plating is a unique and original technique developed by German Kabirski. It creates a deep-black metal coat that is darker and more contrasting than any other plating method. This experimental and closely guarded process allows for the creation of exceptionally striking and unique jewelry pieces.

Oxidized Silver: Plating or Not?

Oxidized Silver is a distinctive technique in jewelry craftsmanship that alters the appearance of silver without using electroplating methods. While it's not considered plating due to its chemical process, German Kabirski includes it in their repertoire for its transformative aesthetic impact.

Oxidation refers to the chemical reaction that occurs when silver is exposed to sulfur compounds or other chemicals. This process forms a thin layer of silver sulfide or other compounds on the surface, darkening the metal and imparting an antique or matte finish. Historically, oxidation has been used to enhance the depth and contrast of silver jewelry, dating back centuries in various cultures worldwide.

Oxidized silver does not involve an electric current or immersion in an electrolytic solution. Instead, it relies on chemical reactions to achieve its desired appearance. Despite this difference, German Kabirski values oxidized silver for its ability to enrich the visual texture and character of their jewelry pieces, aligning with their commitment to innovative and artistic craftsmanship.

Two Tone Plating: Combining Colors

Two tone plating at German Kabirski involves the artful combination of two different metal finishes on a single piece of jewelry. This technique is achieved through meticulous masking and careful application of electroplating processes to achieve a harmonious dual-tone effect.

German Kabirski's process begins with the thorough cleaning and preparation of the jewelry piece. Skilled artisans then carefully mask off areas designated for each metal finish, ensuring clean lines and distinct contrasts. The piece undergoes electroplating, starting with one metal finish and then adjusting the masks to apply the second finish. This methodical approach results in a seamless transition between the two tones, enhancing the overall visual appeal of the jewelry.

German Kabirski approaches two tone plating with the spirit of an artistic visionary—innovative, bold, and always exploring new possibilities. Their designs, featuring combinations like Black or White Rhodium and Gold, showcase this fearless creativity, offering jewelry that's not just beautiful, but daring and distinct.

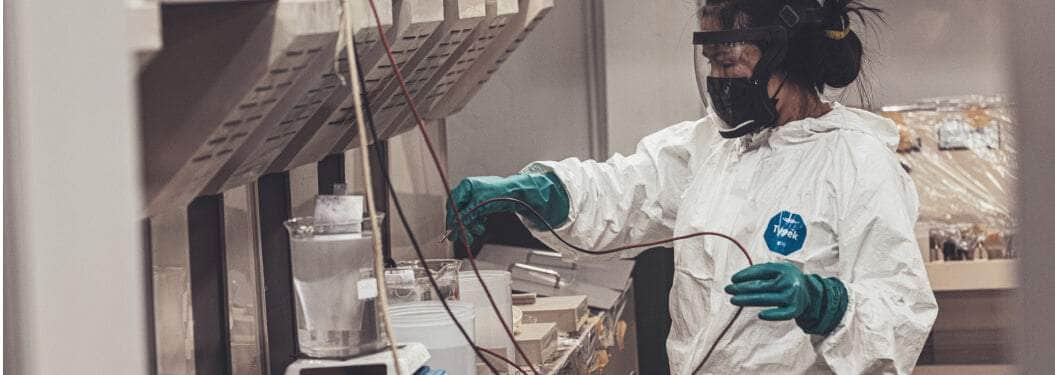

Shout Out to German Kabirski Galvanic Team

Our galvanic processes are carried out at our factory in Bangkok by a dedicated team of artisans who've been with German Kabirski for years. They know all our secret techniques and exacting standards inside out. Always experimenting to enhance the beauty and quality of our jewelry, they ensure every piece meets our high standards.

Share your comment

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.